What is an Automotive Wire?

The first thing that comes to the mind of many when they hear automotive wiring is an AUX cord, internal lighting wire, or an iPhone charger. The truth is, some of these are automotive wires, while others are traditional cabling products used within automobiles.

As the name implies, automotive wiring is used within different automobiles. However, the applications of these products are similar.

Notwithstanding, choosing the wrong automotive wire can be disastrous. Choosing the right wiring product with different configurations and gauges has become increasingly difficult.

Understanding Automotive Wire Types

It is crucial to make the right selection when choosing electrical wire. Since there are many types, understanding the best one for your application can be confusing. It’s worth mentioning the danger that could arise from using the wrong wire.

For instance, using wires intended for households in vehicles can lead to failure and fire if the wire can’t withstand the vibration, heat, and chemical exposure.

Automotive Primary Wire

It is the most widely used wire and is easy to find in auto stores. A primary wire features a multi-stranded core and flexible insulation, allowing it to work in tight spaces.

It is rated from 80 ℃ to 106 ℃, making it excellent for general applications within automobiles and marine vehicles. Primary wire is long-lasting, oil, chemical, and acid-resistant.

More so, these cables are a perfect solution for locations that are hard to reach or areas with harsh weather conditions.

Motor Wire

The motor wire features finer strands of wire, making it possible to handle higher voltages. It is popularly used for the internal wiring of appliances, HVAC equipment, and other automotive applications. It’s resistant to grease, oil, acids, water, solvents, fungus.

SXL Wire

This wire can withstand higher heat, abrasion, and aging than the primary wire due to its cross-linked polyethylene jacket feature. It is an excellent choice if you are looking for durability and is popularly used in racing or industrial vehicles.

Speaker Wire

Speaker wires are used in audio applications. It carries sounds from the stereo receiver to the speakers.

They perform better for low voltage usage and should never be used to carry a heavy load. The positive and negative terminals should be connected correctly to get the best out of your speaker wires.

Battery Cable

Generally, it is used to connect the battery to the car’s electrical system and the ground. It features a larger gauge and heavier wire that are often susceptible to corrosion.

The corrosion occurs inside the cable where it can’t be seen. This corrosion can sometimes lead to starting issues.

Purchasing Automotive Wire

It is crucial to take caution when buying wires and cables, especially at low costs. Many manufacturers create cables with aluminum conductors coated in copper rather than using pure copper. Aluminum conductors don’t do as well as copper in holding a charge.

Choosing the Right Wiring Size

The main issue in choosing wires is getting the correct size. The electric current your wire can carry depends on the length and thickness or gauge of the wire.

However, the size you need will depend on the use. For instance, a signal wire doesn’t need to be big. On the other hand, major power wire applications such as electric motors, alternators, and other high-draw items need a much larger wire to withstand the load.

The distance from the source is also a factor. The farther away it is the diameter increases. Larger gauge wires can also combat the problem of a voltage drop.

Materials Used in Automotive Wiring

The material used in making the wire is as important as what it is used for. Copper is the most recommended material for electrical applications. There are other cheaper alternatives available, including aluminum, copper-clad aluminum.

OFC (Oxygen Free Copper) and CCA (Copper Clad Aluminum) are the two main types of wire. Aluminum conducts only about 60% electricity, heats up more, and is prone to corrosion.

When electricity is added, the natural corrosion process intensifies. Due to the moisture in the air, electrolysis might occur, which reduces the ability of the wire to conduct properly.

If you open up your wire and find it covered in a whitish powder resulting from electrolysis. It also happens with copper wire, but it takes longer, and the cables turn green.

Automotive Wiring: The Basic Tools to Have

With the proper tools, your wiring job can be a lot easier. Here are some must-have tools

Wire Stripers

A set of quality wire strippers will include a group of holes to fit most wire gauges. Its function is to help strip your wire insulation effectively without cutting off the wire conductors by accidents.

Wire Crimper

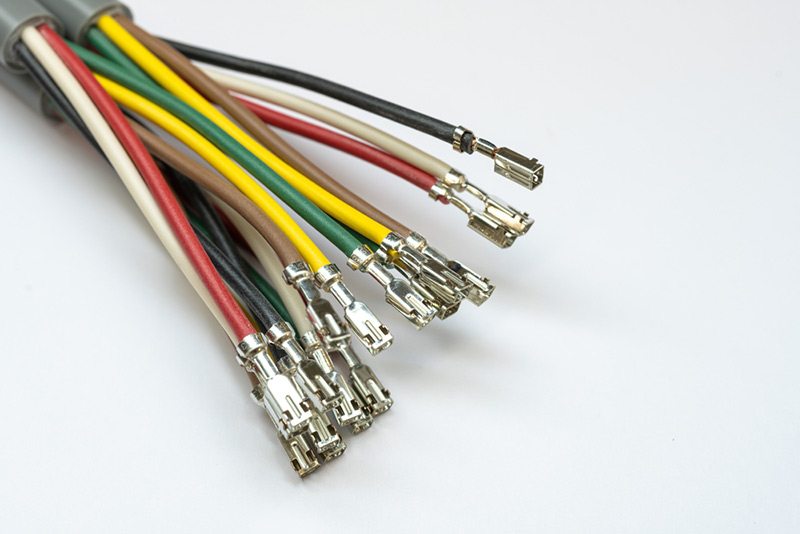

A good wire crimper is necessary for the installation of solderless connectors. With a quality crimper, you can get wire cutting and stripping sections and two to three sections on the nose to fit various lug sizes.

A Soldering Iron

You will need a soldering iron for oversized connectors that can’t be crimped. It is also used for splicing wires. However, you will need a solder explicitly made for electronics and wiring.

It comes with a mildly activated rosin core flux that helps clean the heated wire removing oxidation and corrosion. With a good soldering iron, you can solder with less heat making the connections stronger with less electrical resistance. Other tools to have include;

A Wire Brush-To remove corrosion oil or grease before soldering

Shrink Tubing-Used to insulate connections from outside elements

A Test Light– This helps you test for power within a circuit.

Automotive cables can be used for different applications such as primary wires, battery cables, etc. It’s essential to work with high-quality manufacturers.

We have a variety of colors and gauges available and a team of experts to help you make the right choice. Feel free to contact us for more information or visit our website now.